17 June 2020

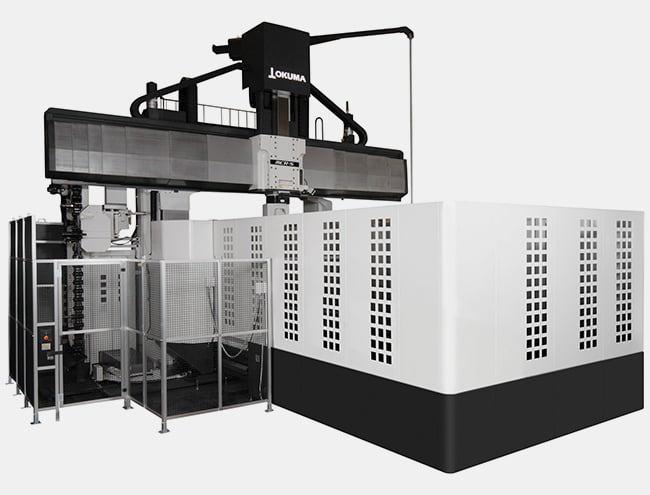

Innovation in mould production with the new series of gantry machining centres Okuma MCR-S

Series MCR-S is the latest Okuma innovation in the production of double-column machining centres, the result of almost 60 years of experience in the construction of gantry centres, a combination of the double-column structure made entirely of cast iron, electronics and software managed by the OKUMA OSP-300 numerical control, fully developed in Okuma plants, which enhances the performance of machining during roughing, semi-finishing and finishing operations, reducing working times and enhancing the quality of the final surfaces.

Okuma is increasingly investing in the development of software that simplifies and reduces machine set-up times, which are essential for reducing costs. One of these software is the Collision avoidance system CAS, which is fundamental on complex machines to simulate, verify and anticipate possible collisions. Another key software to optimize the process is the SERVO NAVI technology that improves cycle times and accuracy. This software automatically detects the load on the table and adjusts the best acceleration and deceleration speed in order to obtain faster cycle times and to use the electronics and mechanics in the best possible way.

Another indispensable software on large machines is the Thermo-Friendly Concept, a concept that starts from the symmetrical design of the machine structure to handle the problem of thermal expansion and address this element that cannot be eliminated. The combination of Okuma hardware and software ensures extremely accurate thermal compensation by managing expansion at any time of day from 0.1 micron. It also guarantees an unparalleled dimensional stability for all operations in non-air-conditioned working environments but with temperature variations of 9° over 24 hours, eliminating manual adjustments by the operator. It also guarantees machining with millesimal tolerances and avoids loss of time for long heating operations, thus reducing energy costs and non-productivity costs. The MCR-S series was presented during EMO 2019.