Technical specifications

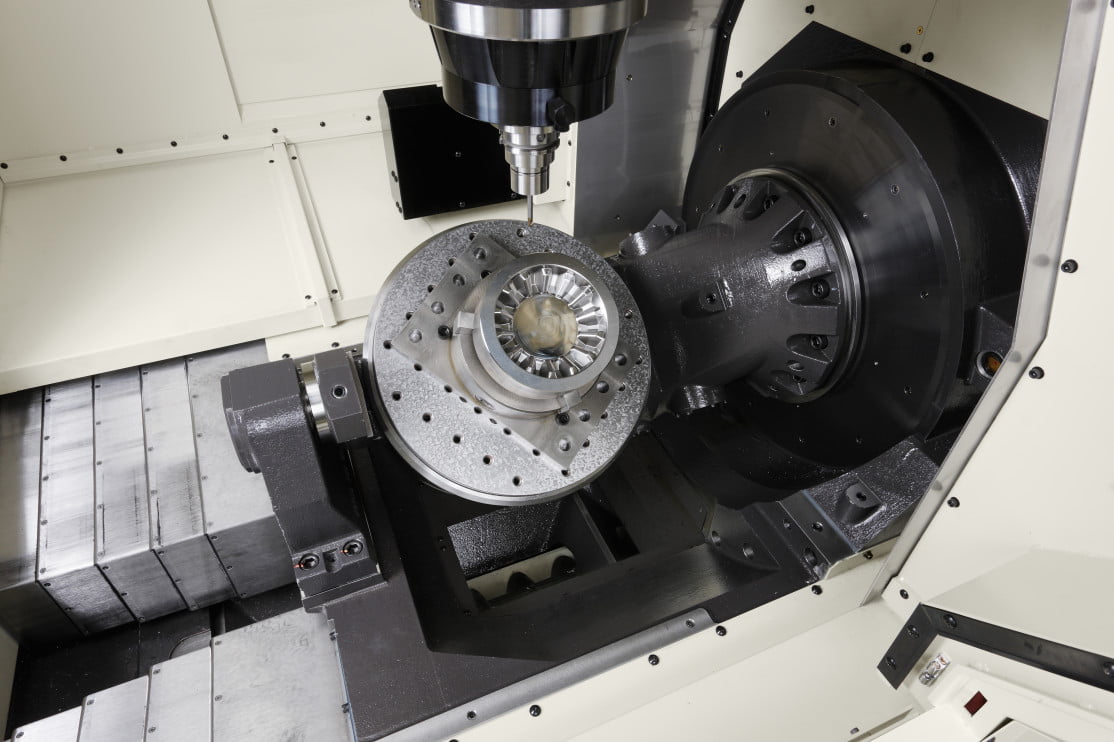

| Technical Data | |

|---|---|

| X- Y- Z axis travels [mm] | 900 x 500 x 450 |

| Work table dimensions [mm] | Ø 400 |

| Maximum table load [kg] | 300 |

| Spindle rotation [rpm] | 24000 |

| Storage capacity | 60 seats |

| Rapid strokes X-Y-Z [mm/min] | 20000 |

| Maximum part diameter | 500 mm |

Discovery also

Excellent products and continuous training. Celada is the trusted partner you were looking for.

Company with ISO 45001 system certified by DNV