Technical specifications

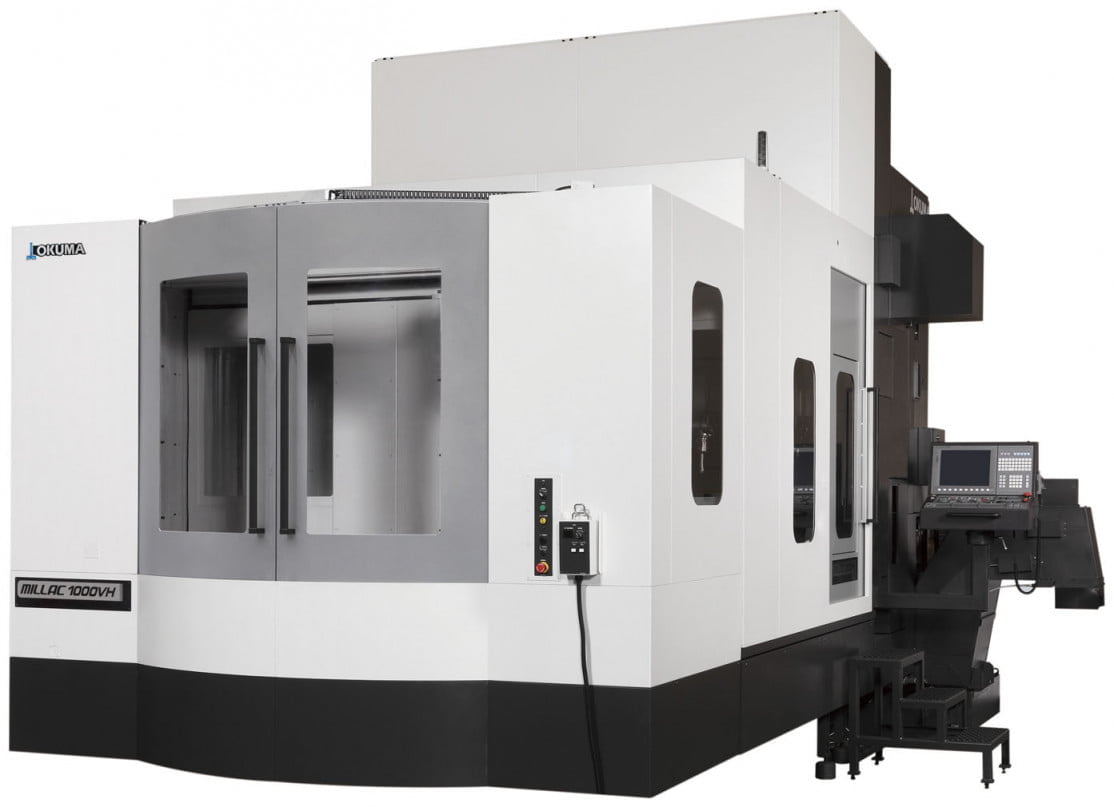

| Technical Data | MILLAC 800VH | MILLAC 100VH |

|---|---|---|

| X- Y- Z axes travels [mm] | 1020/1020/1020 | 1.850/1.300/1.000 |

| Number of tools | 80 | 400 |

| X- Y- Z rapid travels [m/min] | 30/30/30 | 24/24/12 |

Discovery also

Excellent products and continuous training. Celada is the trusted partner you were looking for.

Company with ISO 45001 system certified by DNV